Process

"Design and fabricate an artifact that will provide a deep look at humanity, last for thousands of years, and endure the 238,855 mile trek to the Moon…"

“a diverse view of humanity…in no more than 8 ounces of total payload.”

This seemingly impossible charge could only be realized through persistent iteration. For more than 4 years, our design team developed numerous concepts that satisfied our design criteria and met the extreme technical requirements for space travel. Through multiple cycles of development, deep engagement with obscure subject matter, piles of discarded concepts, and heaps of patience, we’ve arrived at something unique and now reflect on lessons learned and insights for future space missions. The culmination of our thinking, best practices in rapid prototyping and meticulous hand work is embodied in the form of the MoonArk as a testament to avant-garde material practices. With the MoonArk launching in 2023, we will turn our sites towards future space missions and the concepts of additional markers that leave material traces of humanity throughout the galaxy as ways to celebrate and decode the complex beauty of life on Earth.

See more

-

Confirming field dimensions before we cut metal for the murals

-

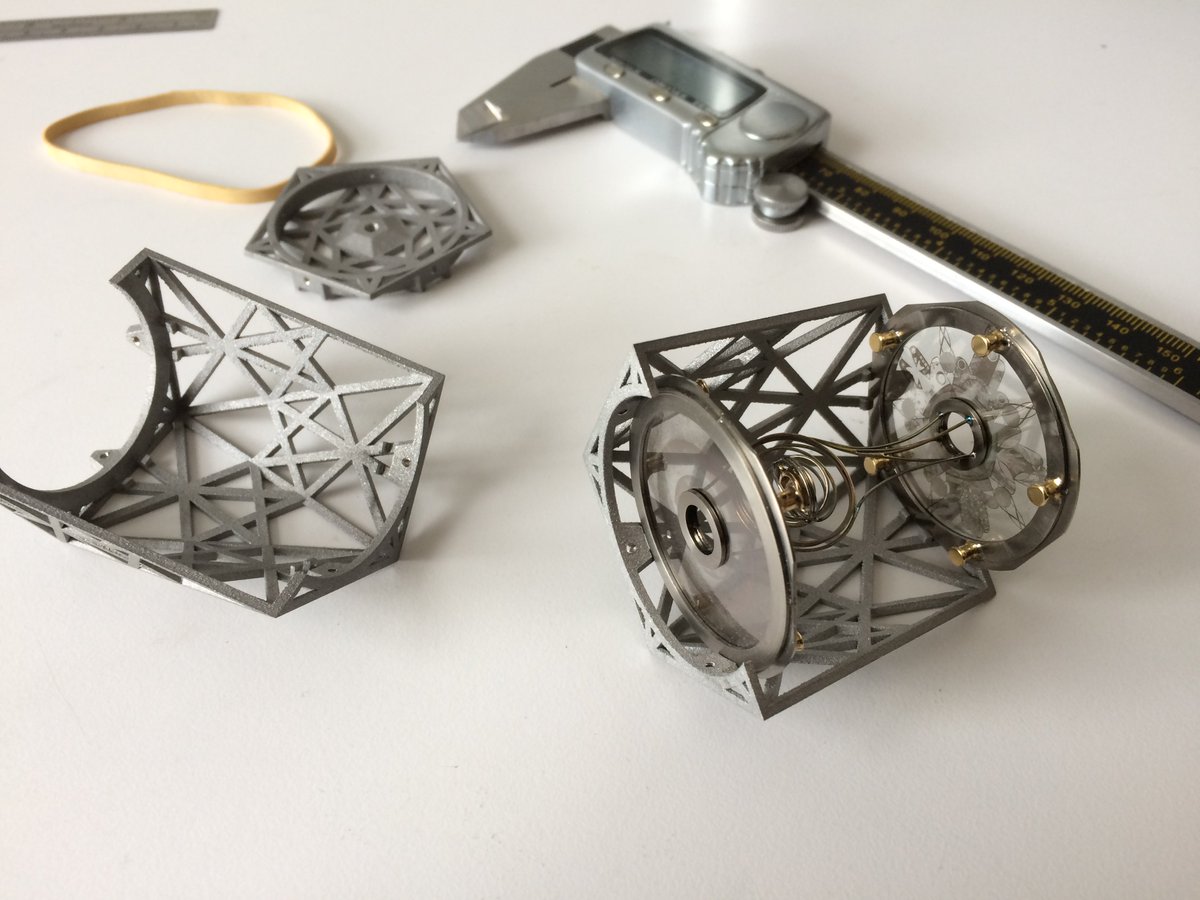

Mark Rooker working components in his lab at James Madison University

-

Laser engraving a metal mural at MECCO in Cranberry, Pennsylvania

-

Components arranged and organized for assembly

-

Mark Rooker and Mark Baskinger confirming fitment of the stacked cages

-

Matt Zywica, Mark Baskinger, Mark Starnes, and Mark Rooker reviewing protocol for material handling and and component fabrication